We Build Your Dream

Home

Trusted Construction Company

Our Services

Design & Build

In Design and Build Services our construction company is responsible for the entire project from start to finish, including design, engineering, construction, and project management. This meaans that the construction company takes on the responsiblity of designing and building the project within the client’s budget and schedule.

Renovation

A renovation and construction company may work with a variety of clients, including homeowners, property managers, commercial building owners, and government agencies. The company’s team of professionals, including architects, engineers, and contractors, work together to create a renovation plan that meets the clients’s specific needs and budget.

General Engineering

General engineering services include a wide range of activities, including feasibility studies, conceptual and detailed design, project management, construction supervision, and commissioning. The services can be applied across various sectors, such as civil engineering, mechanical engineering, electrical engineering, environmental engineering and many more.

Other Services Sewage Treatement Plant

A sewage treatment plant, also known as a wastewater treatment plant, is a facility designed to treat and purify wastewater generated from residential, commercial, and industrial sources. The treatment process involves a series of physical, chemical and biological processes to remove pollutants and contaminants from the wastewater before it is released back into the environment.

Get a quote for your project

Latest Projects

CALAMBA, LAGUNA

Our Spanish theme 1100 sqm three-storey residence project is an ongoing architectural endeavor that aims to capture the essence of traditional Spanish design in a modern setting. This residence promises to be a captivating fusion of classic Spanish elements and contemporary aesthetics.

This elegantly designed space showcases timeless architectural elements with a focus on durability and spaciousness. From the intricate detailing to the wide-open interiors, every aspect reflects a commitment to quality and sophistication, creating an inviting atmosphere that is both beautiful and enduring.

SAN PEDRO,LAGUNA

CANLUBANG, LAGUNA

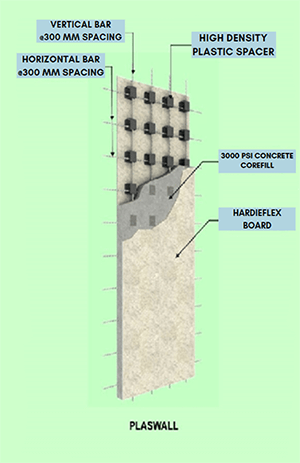

PLASWALL

BUILDING SYSTEM

Plaswall Building System (Cast in PLace) is more than 18years Building Innovative System in the Philippines use in the Housing Construction Industry as an alternative to conventional system. It provides Clean, Tidy Construction Environment, estimated 15% faster compare to conventional system. Plaswall is a hollow Permanent Form Works a components of Fiber Cement Boards as the outer skin of the Panel and a High Density Plastic Block Spacer that servers as the separator, which makes the panel as one composite.

It is design to pour concrete in-place by Job mix from 3000psi Concrete Design to a Higher Density depending on the level of the Structures. it eliminates the columns since the wall itself is already a Load Bearing Wall

Prior concrete pouring all embedment items should be in placed i.e., MEP’s Roughing-in, Reignforcement bars, Jambs of door & Window should be installed. Therefore it will eliminates chipping works, Plastering and ready for Joint rendering and painting after concrete pouring.

PLASWALL PANELS

Advantages Using Plaswall Panels

- Easy to Install

- Fast clean method of building compared to conventionals

- Wastages minimized as prefabricated to order or fabricated in site

- Utilizes existing tools and equipments of conventional builders

- High quality of finish virtually guaranteed

- Suitable for even reclaimed and backfilled locations

- Minimizes Forms Works

- Concreate and other materials volume usage exact and predictable

- Predictable build times and build costs

- Easy for conventional builders to use and learn

- Durable finish minimizing reworks and repaires

- Earthquake and typhoon resillent comparable to conventional

THERMA

WALL PANELS

Thermal Insulation may be added to our walling systems either internally or externally, however our recommendation is insulation applied externally in the form of a laminated sandwich (Thermal wall) or a external insulation system product.

Polystyrene foam is generally has a higher R-value per unit of thickness. Foam-in-place insulation can be blown into small areas to control air leaks, like those around windows, or can be used to insulate an entire house.

In the context of the construction, the R-value is a measure of how well a two-dimensional barrier, such as a layer of insulation, a window or a complete wall or ceiling, resists the conductive flow of heat. It is the temperature difference per unit of heat flux between the warmer surface and colder surface of a barrier under steady-state conditions. The measure is therefore equally relevant for lowering energy bills for heating in the winter, for cooling in the summer and for general comfort.

An R-value can be given for a material (e.g. for polyethylene foam) or for an assembly of materials (e.g. a wall or a window) R-values are additive for layers of materials and the higher the R-value better the performance.

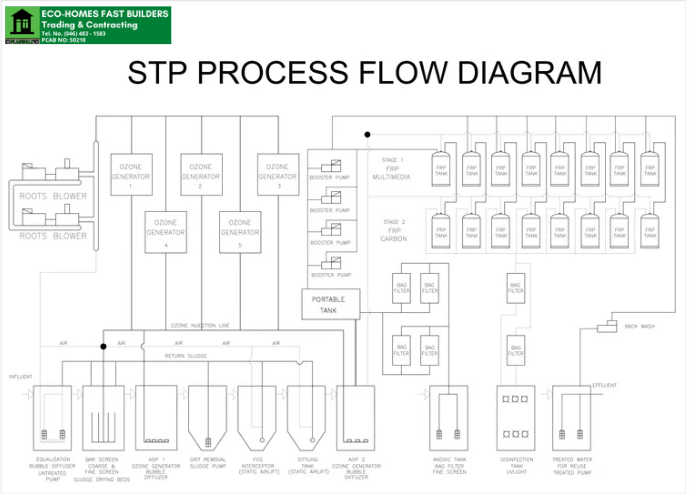

ADVANCE OXIDATION PROCESSESS SEWAGE

TREATMENT PLANTS (STP)

(USED RADIATION AND OZONE-BASED PROCESSES)

We Design & Build

Supply of Equipment’s

Erect and Commission

Operation and maintenance of Effluent Treatment Plant (ETP)

Proven to pass DENR / LLDA Effluent Standard (DAO 2016-08 / DAO 2021-19)

SYSTEM ADVANTAGE

- Fully Automated System

- No chemical or enzyme needed

- Low electrical power consumption

- No foul odor

- Low maintenance

- No Operator needed

- Recyclable water

AOP SYSTEMS FLOWCHART

EQUALIZATION

– wastewater is aerobically treated using oxygen generator which produces high volume of dissolved oxygen.

BARSCREEN

– to arrest large solid materials

SLUDGE DRYING BEDS

– collecting sludge

AOP 1

– destroy and remove the organic contaminants in water

– disinfection is also introduced at this stage

CREATE REMOVAL TANK

– services as primary treatment where heavy solid and ligher scum seperate from wastewater

FAT OIL AND GREASE (FOG)

– a tank provided to received oily resident coming from the oily water filtering or seperating equipment and from the purification of fuel and lubricating oils

SETTLING TANK

– this is a retention tank where very fine solids are allowed to settles prior to transfer to the bag filter

AOP 2

– dissolve sludge using ozone generator instead of chemical

– turbidity is greatly reduced and clarify of wastewater is observerd

– continues disinfection is in effect at this stage to meet the total coliform requirements of DENR

– BOD / COD levels are also reduced at this stage

ANOXIX TANK

– this is where the settled solids are anaerobically digested resulting to reduced volume of solid in the process

DISINFECTION TANK

– to arrest the color and eliminate bad color.

FILTERS

– where fine floating particles are filtered to meet the total suspended solid requirements of DENR